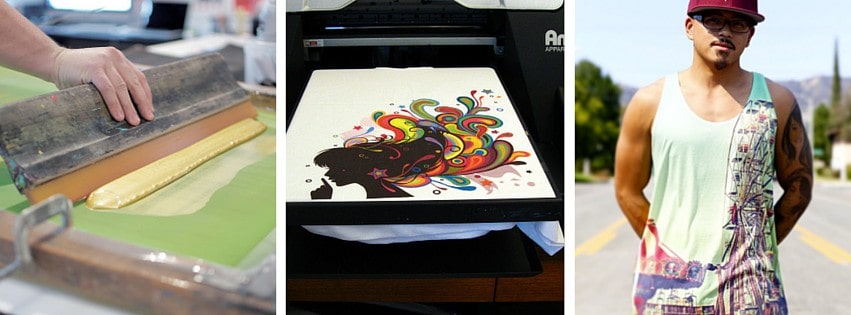

Sublimation printing is a process where heat will transfer dye onto a plastic material. The sublimation effort allows the solid transfer to convert to gas without entering a liquid stage, thus penetrating the print surface. It is a unique process suitable for many custom printing needs.

Sublimation printing provides many positives that make it a useful solution for your work needs. But there are some negatives you should also note surrounding how well a printer can work, including how it compares with other common printing solutions.

Contents

Advantages and Disadvantages of Sublimation Printing

Might be useful: How to Choose a Sublimation Printer

Pros

Sublimation printing produces a consistent tone on everything it touches:

Each dot of sublimation ink can feature a different color. The design produces a high-resolution look that features a distinct appearance you will appreciate.

You don’t have to wait for the fabric to dry when the project is complete:

The sublimation process ensures the ink won’t enter a liquid form. You can remove the shirt from the press and fold it up right away without worrying about smearing.

There are fewer moving parts involved with sublimation printing:

The thermal process does not have to move around to create a printout. The printing head stays in one position and responds to the fabric in moments. Since there are fewer moving parts, the machine is also durable. It will not potentially break down or fail to work often. The design can also read the cartridge in moments to create an accurate printout for all the colors you will use.

The dye will move into the fabric and become part of the product, ensuring it will not fade:

In addition to moving directly into the fabric, it goes far enough to where it will not break apart or fade. It will not be harmed by water either, meaning it stays comfortable in all conditions.

The process does not require much energy:

The heating system does not require extensive energy, nor does it require any outside ink or water. You only require the press material you will use when producing your image to make this part work.

You can produce more detailed images through a sublimation printer than if you used a heat press:

A sublimation printer can manage multiple colors and even highly-layered designs. It works better than a heat press that might require multiple applications to produce something.

The design you produce through sublimation is durable:

Sublimation has a significant advantage over screen printing in that the design you produce won’t crack, fade, or wear. The process is more elaborate than screen printing, an effort that produces a graphic on top of your fabric. Screenprints can crack and wear, plus they may not last in a traditional wash.

Cons

You can only use sublimation printing on light-colored plastics:

The dyeing process does not work well on dark surfaces. The items on your sublimation material should be dark enough to handle most projects. This point is different from heat pressing, a process that works with all fabrics.

Any dark items you will use in the printing effort must be treated with a suitable polymer:

A dark-colored surface might have a body that doesn’t respond well to printing dyes. A separate polymer would have to be applied on its body to make it work, and that might not be as effective as you would hope.

You would require specialty ink that works for thermal printers:

The ink should be something that can resist a potential liquid state. The ink can come from a specialized cartridge, but that might not be as easy to find.

It costs more to use a thermal printer:

The cartridges necessary for your thermal printer can cost more to use than others. Some of the materials you use here may not be easy to recycle.

Sublimation printers take a while to produce an image:

The process requires you to print transfer paper and then press each item separately. You can produce about sixty pieces in an hour through sublimation. This process is slower than screen printing, a practice that lets you produce hundreds of something in an hour. But the longer timeframe for sublimation is mainly due to the process being more detailed and providing more durable layouts.

Some printers may produce slight fumes that can irritate people:

Sublimation inks might produce uncomfortable vapours. This problem occurs more often with cheap cartridges and ink products.

For larger needs, you can go for Heat Press Machines.

Is Sublimation Printing Right For You?

Sublimation printing works well if you know where you’re going with your work at hand. Be certain when managing a sublimation printing project that you can find something for the task that can work with your fabric and the design you wish to plan. Knowing what makes it fit will be essential to your success.